Hexagonal boron nitride (α-BN) often is called white graphite, because it has a graphite-like hexagonal layer structure. In contrast to graphite, however, BN is white and has a high electrical resistance. The reason for these differenees is the absence of the delocalized π-bonds in the BN structure.

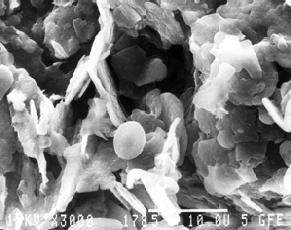

Fig. 1. SEM micrograph (secondary-electron image) illustrating the platelike particles of a refractory-grade BN powder and a sphere of molten B2O3 (center) that was not converted to BN during synthesis.

BN is a ceramic material with outstanding chemical, thermal and electrical properties. It can be used as a high-temperature solid lubricant, is stable at high temperatures and is not wetted by many metallic melts, such as aluminium and magnesium. BN shows good thermal shock resistance, high thermal conductivity and low dielectric constant. Therefore, it is a nontoxic substitute for beryllia in certain electronic applications.

BN does not occur in nature. It was first prepared in 1842 by reacting molten boric acid with potassium cyanide. In the 1950s, commercial production was initiated by Union Carbide and Carborundum Co. Three general reactions are used for the synthesis of α-BN:

B2O3 + 2NH3 → 2BN + 3H2O (T = 900°C)

B2O3 + CO(NH2)2 → 2BN + CO2 +2H2O (T > 1000°C)

B2O3 + 3CaB6 + 10N2 → 20BN +3CaO (T > 1500°C)

These processes yield refractory grades with concentrations of 92%-95% BN and 5%-7% B2O3. The glassy B2O3 cannot be converted to BN. The B2O3 is removed by evaporation in a second step by reheating the product to temperatures >1500°C. The remaining ceramic-grade product has BN concentrations >98.5%.

Composition by supplier(%) |

||||

Component |

A* |

B* |

C* |

D* |

Boron |

42.2 |

43-44 |

43 |

42.5 |

Nitrogen |

55.8 |

54-55 |

54.5 |

55.5 |

Oxygen** |

0.5 |

1.5 |

1.5 |

0.5-1.0 |

Carbon |

0.2 |

NA |

0.1 |

0.1 |

B2O3 |

NA |

0.1 |

0.1 |

0.15 |

Metallic impurities |

0.1 |

0.2 |

0.2 |

0.1 |

Table 1. Commercially Available Ceramic-Grade BN Powders

_____________

* NA is data is not available.** includes oxygen content of B2O3

BN production figures are not included in statistical reports. Estimates, however, show production of 220-250 metric tons in 1994 for the western world. Companies involved include Advanced Ceramics Corp. and Carborundum Co. in the United States; Boride Ceramics & Composites Ltd. in the United Kingdom; Elektroschmelzwerk Kempten GmbH and H. C. Starck GmbH & Co. KG in Germany; and Denki Kagaku Kogyo, Kawasaki Steel Corp., Shin-Etsu Chemical Co. Ltd. and Showa Denko KK in Japan.

Costs of BN powders are about $70-$80/kg for refractory grades and $100-$120/kg for ceramic grades, with little or no increase expected for the near future. High-purity grades can be purchased at $200-$400/kg, depending on quality and size of order.

Composition by supplier(%) |

||||

Component |

A* |

B* |

C* |

D* |

Boron |

41.5 |

42-45 |

41.5 |

41.5 |

Nitrogen |

53.5 |

50.5-53.4 |

51.5 |

52.0 |

Oxygen** |

3.5 |

5.0 |

7 |

5 |

Carbon |

0.4 |

NA |

0.1 |

0.2 |

B2O3 |

NA |

1.0 |

7 |

5 |

Metallic impurities |

0.1 |

0.2 |

0.2 |

0.1 |

Table 2. Commercially Available Refractory-Grade BN Powders

_____________

* NA is data is not available.** includes oxygen content of B2O3

BN powders are used for the production of TiB2/BN intermetallic composites used as evaporator boats for vacuum metallization of plastics and glass. Dense shapes, e.g., crucibles and break rings for horizontal continuous steel casting, are made by hot isostatic pressing, using B2O3 as a sintering agent. α-BN also is the starting material for the synthesis of cubic boron nitride (β-BN), a dense, diamond-like modification, with zinc blende structure. β-BN is the second hardest material known.

Use |

Consuption (metric tons)* |

TiB2/BN composites |

60-70 |

Refractory applications |

20-30 |

Break rings |

20-30 |

Cubic boron nitride |

15-20 |

HIPed shapes |

15-25 |

Paints/coatings/lubricating agents |

25-35 |

Electronic applications |

NA |

Table 3. Boron Nitride Powder 1994 Estimated Consumption

_____________

*NA is data not available.

The extremely good high-temperature lubrication and nonwetting properties of BN are used in coatings in the production of aluminium and magnesium castings as well as glass-forming and superplastic forming of titanium sheets for aerospace and defense applications

These paints and lubricating coatings are suspensions of BN in a carrier (mainly water for safety and environmental considerations), often blended with binders and rheological additives. Some formulations are available as aerosols. BN coatings are produced by Advanced Ceramic Corp. and ZYP Coatings Inc. in the United States and by Büro für angewandte Mineralogie and Elektroschmelzwerk Kempten GmbH in Germany.

Stephan Rudolph, Büro für angewandte Mineralogie

from: American Ceramic Society Bulletin, 74 (1995) 6, pp. 115-117

![]() Download entire publication as pdf.

Download entire publication as pdf.

© 2023 Büro für angewandte Mineralogie · Dr. Stephan Rudolph · D-47918 Tönisvorst

These recommendations are believed to be correct. However, no guarantee of their accuracy is given. Therefore, purchasers shall make their own tests to determine suitability for their use. These products are offered for industrial and related uses (e.g. research and development) only. However the user must take the necessary precautions appropriate for products containing chemicals. This description does not imply the absence of any patents, the responsibility whatsoever solely rests with the user.

www.a-m.de